Minimum Design Metal Temperature or MDMT is the lowest temperature that a piping system with specified material and thickness can withstand. While designing piping systems (equipment) in cold regions where the environment temperature falls drastically or piping systems carrying cryogenic temperature fluid, MDMT is a critical factor. Considering the metal’s resistance to brittle failure, MDMT is the lowest permissible metal temperature for that thickness.

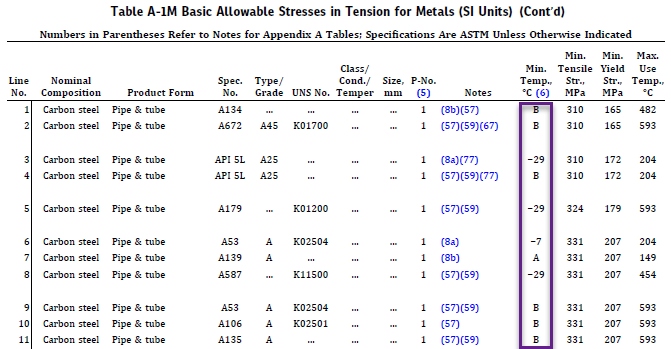

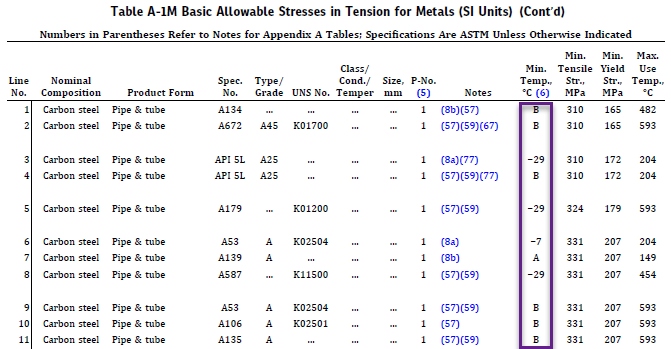

The piping designer shall verify that materials are suitable for service throughout the operating temperature range (maximum and minimum possible temperatures). Table A-1 and Table A-1M of ASME B31.3 code contain the minimum design metal temperature for which the material is normally suitable without impact testing. Refer to Fig. 1 where minimum design temperatures for a few carbon steel pipe materials are highlighted.

Below -29°C, ductile Carbon steel starts converting into brittle material. So impact test requirements as per the code arise as brittle carbon steel can easily fail catastrophically. However, the code provides few rules to use such materials below its minimum design metal temperatures as provided below:

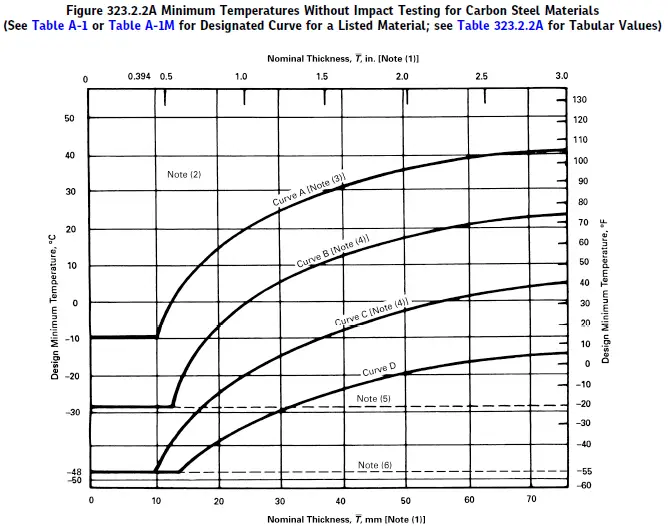

The use of a material at a design minimum temperature colder than −29°C (−20°F) is established by para. 323.2.2 and other impact test requirements. For carbon steels with a letter designation in the Minimum Temperature column, the curve in Figure 323.2.2A of ASME B 31.3 (Reproduced in Fig. 2) is used. MDMT depends on the nominal thickness.

Impact testing of the base metal is not required if the design minimum temperature is warmer than or equal to the calculated value of MDMT.

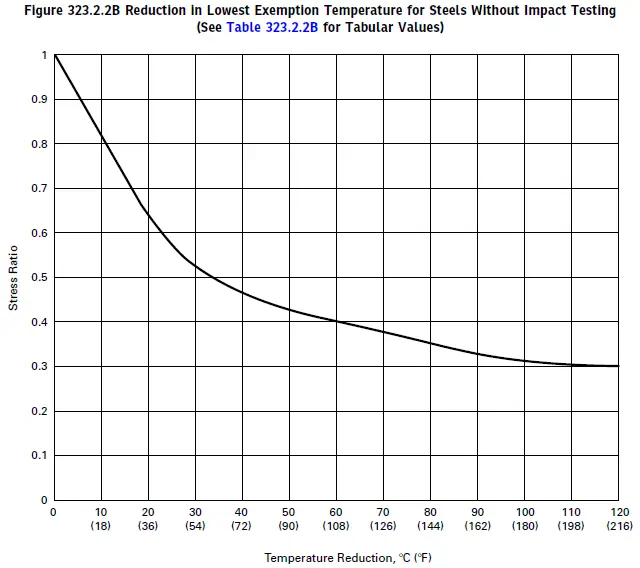

READ What is an Access Fitting? Applications, Types, and Components of Access FittingsHowever, for steels, impact testing is not required if the stress ratio “r” 323.2.2 (b) is 0.3 or less, and the design minimum temperature is warmer

than or equal to −104°C (−155°F), and temperature reduction may be used if 323.2.2 (c) rules are satisfied:

(1) The piping is not in the Elevated Temperature Fluid Service.

(2) Local stresses caused by shock loading, thermal bowing, and differential expansion between dissimilar metals (e.g., austenitic welded to ferritic) are less than 10% of the basic allowable stresses at the condition

under consideration.

(3) The piping is safeguarded from maintenance loads, e.g., using a valve wheel wrench on a small-bore valve.

Also, for carbon, low alloy, and intermediate alloy steel materials (including welds) that have not been qualified by impact testing, the minimum temperature from Table A-1, Table A-1M, or Figure 323.2.2A may be reduced to a temperature no colder than −48°C (−55°F) by the temperature reduction provided in Figure 323.2.2B if 323.2.2 (c) rules are satisfied.

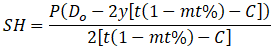

The stress ratio “r” is calculated as the maximum value from the following:

mt% – mill tolerance, C – corrosion allowance, S – allowable stress

The latest version of professional PASS/START-PROF software includes the ability to check automatically if the impact test is needed or not.

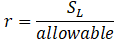

READ Rupture Disc: Definition, Types, Components, Selection, Sizing, Advantages, InstallationFirstly, the PASS/START-PROF has a material database that includes the minimum metal temperature for all materials. For carbon steels with a letter designation in the Minimum Temperature, PASS/START-PROF calculates the minimum metal temperature automatically, according to Figure 323.2.2A.

Secondly, the software automatically calculates “r” values for all operating modes of the piping system. And has the special option “Use MDMT Allowable Reduction” in project settings to verify if the temperature reduction is allowed or not as shown in Fig. 5

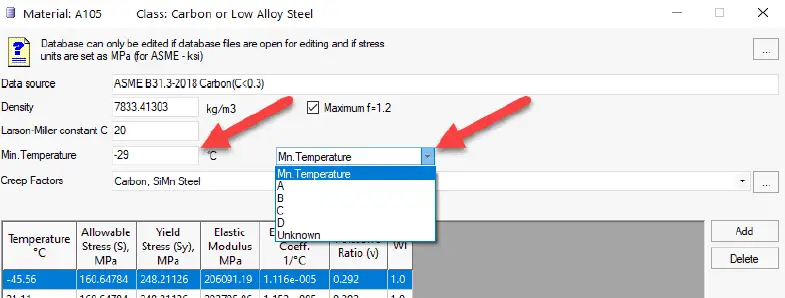

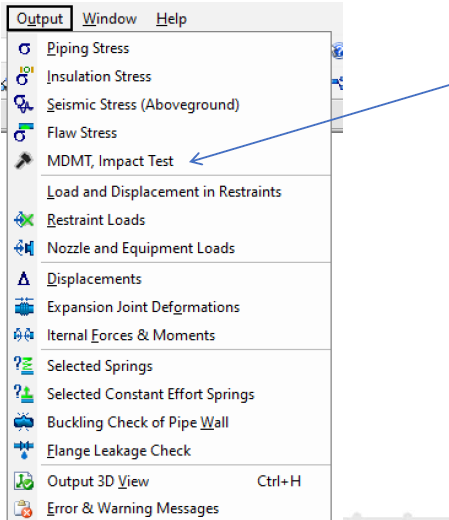

Thirdly, for each pipe element in the system, the software determines if the impact test is needed or not according to the previously described rules of 323.2.2 (a), (b), (d), (e), (f), (g), (h), (i), (j) ASME B31.3-2018. The result is shown in the special MDMT table as shown in Fig. 6 below:

After analysis, if the minimum design or ambient temperature from all operating modes is lower than the calculated MDMT value, the “Impact Test” requirement note is printed. Otherwise, the result simply shows “OK” for proceeding further.

To avoid impact testing, the stress ratio “r” value should be reduced as low as possible for the critical piping system elements. To do this, you need to create the piping stress analysis model in PASS/START-PROF and reduce the sustained and operation stresses by adding more support or flexibility to the piping system.

READ What is a Threadolet Fitting? Threadolet DimensionsMore information about the new modern pipe stress analysis software PASS/START-PROF you may learn from the resources web page.